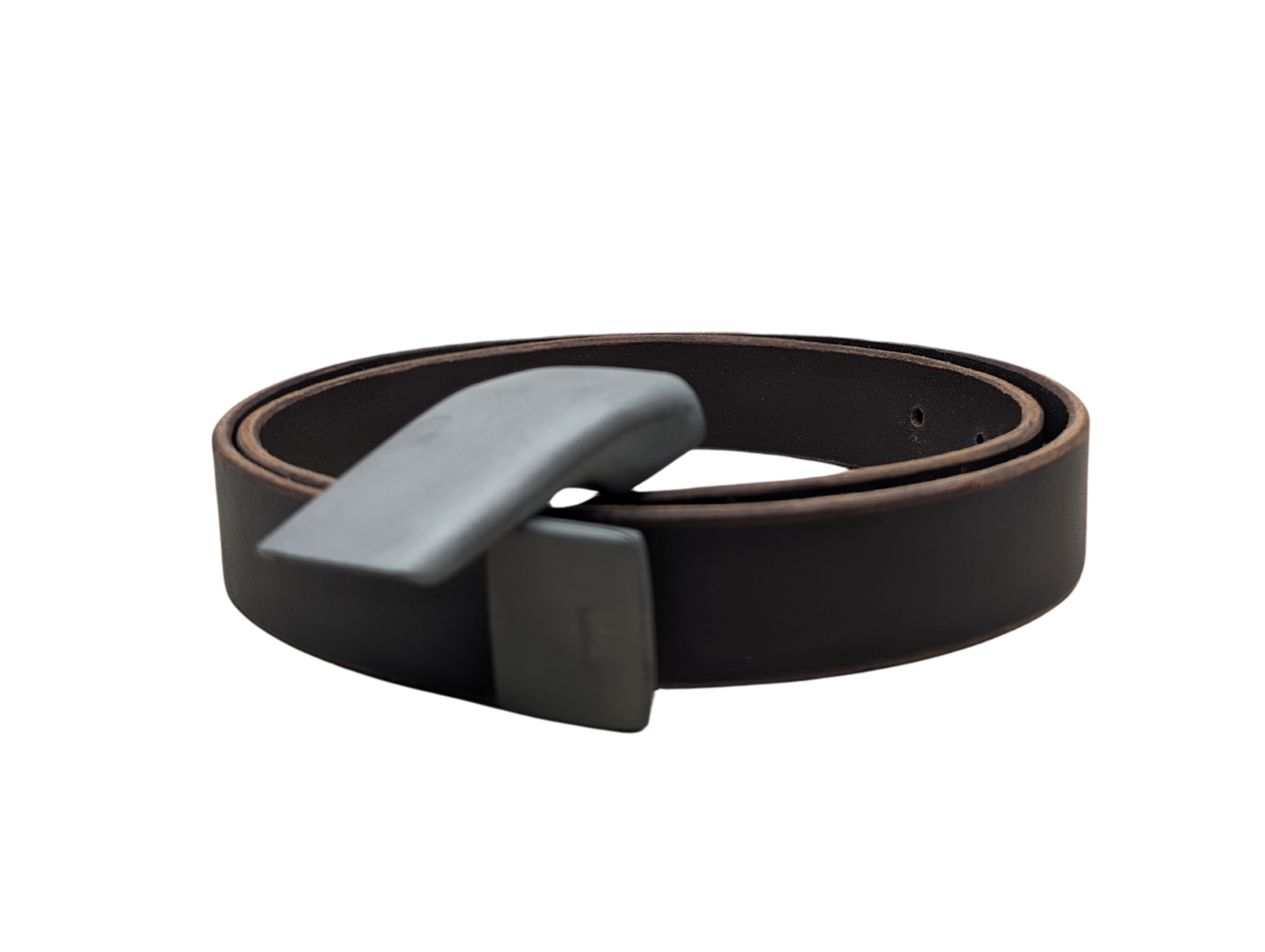

Men's leather belts; what is the best leather to use so you love it?

To most of us leather is leather but as we start to make our men's leather belt and went deep into a discovery about the material properties of various types of leather it became clear this was anything but the case.

Firstly, for this post, we're going to be simply talking about leather from a cow. Adding other animals or even non-animal based leathers (which we write about more in our article on real leather belts) adds even more complexity on top.

What affects the choice of leather in a men's leather belt?

The four main facets that impact the leather being the best choice for our YOKU men's belt are

- Where on the cow it comes from

- What part of the hide you use

- How it has been manufactured

Where on the cow it comes from

A belt is basically a long, thin rectangle. A YOKU men's belt needs to have a certain thickness for our patented no moving parts buckle to work. In contrast a cow is an organic shape with natural undulations in thickness and material properties that vary across the hide of the animal.

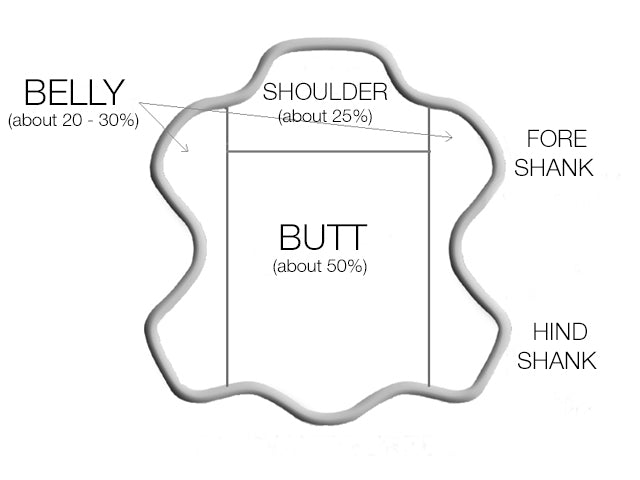

This diagram helps to understand (credit to Leather Dictionary) some of the main areas of a hide

In short the Shoulder is too irregular shaped to create long thin rectangles and the Belly is not the thickest or strongest part of the hide. The only real option to create a long last men's belt is to use the Butt. YOKU men's belts are made from Full Grain Leather from the butt of the animal.

What part of the hide is used for a men's leather belt?

To explain why we we use Full Grain Leather for our YOKU men's belt we need to firstly explain the various parts of a leather skin.

The image above represents the key areas of the leather from the outside skin and hair through what is known as the grain. This is where the collagen that makes up the leather is tightly bound (ie strong). About 4mm in (depending on where on the cow but assuming butt) the grain transitions to the corium and the density of the collagen reduces until we get to the corium which is loosely bound collagen.

The area marked as Full Grain is the strongest, most durable and natural part of the hide. It includes all the markings on the skin that come from the life of the animal and other than the hair being removed nothing is done to the leather. The secondary bracket shows top grain leather, which is still of very high quality but has had the skin removed. Usually this is done to create a very flat surface on which to emboss or embellish the leather. A YOKU men's belt is an expression in minimal design aesthetic so Full Grain leather that preserves the original nature of the hide and also gives us the most durable leather is our choice.

How it has been manufactured

Somewhat related to the area of the leather used described in the previous section but there is a set of manufacturing choices that take your leather and turn it into the belt you actually get in a YOKU men's belt

The first of these is tanning, the way in which the belt gets its colour. The two options available are Vegetable Tanning and Chromium Tanning.

Vegetable Tanning

This traditional method has been around for hundreds of years, it takes a long time, relies on tannins and has a smaller set of available colours but is the gold standard, especially for belts (where durability is required) and especially for a YOKU belt where sustainability and a preference for 'one less thing' is core to our brand (read more about our brand here).

Chromium Tanning

This method which came about in the 19th century uses chromium 3 sulphites to dye the leather in a matter of days. It affects the material properties of the leather that might be desirable in other use cases (softer for example) but are not specifically what we are looking for in a YOKU men's belt. It is regularly cited for its non-environmentally friendly credentials, the byproducts from the process are/can be toxic however there are definitely tanneries who have implemented processes to resolve these challenges. This comprehensive article has more.

YOKU belts are made from either vegetable tanned leather. or chromium tanned leather. We don't use any leather unless the tannery meets our stringent needs around sustainability and durability.

The other aspect of the manufacturing process is the finishing of the belt itself. In short, there is a LOT you can do to a plain leather belt strap, most of it creates no functional value and potentially reduces the material properties or overall durability. The various finishes include sanding, bevelling, burnishing, waxing, stitching and embossing.

The choice of leather often impacts the finishes.

For example if you have bonded leather then the glue between the two pieces of leather is a weak point so a way around this would be to use stitching to strengthen the bond between these two pieces of leather.