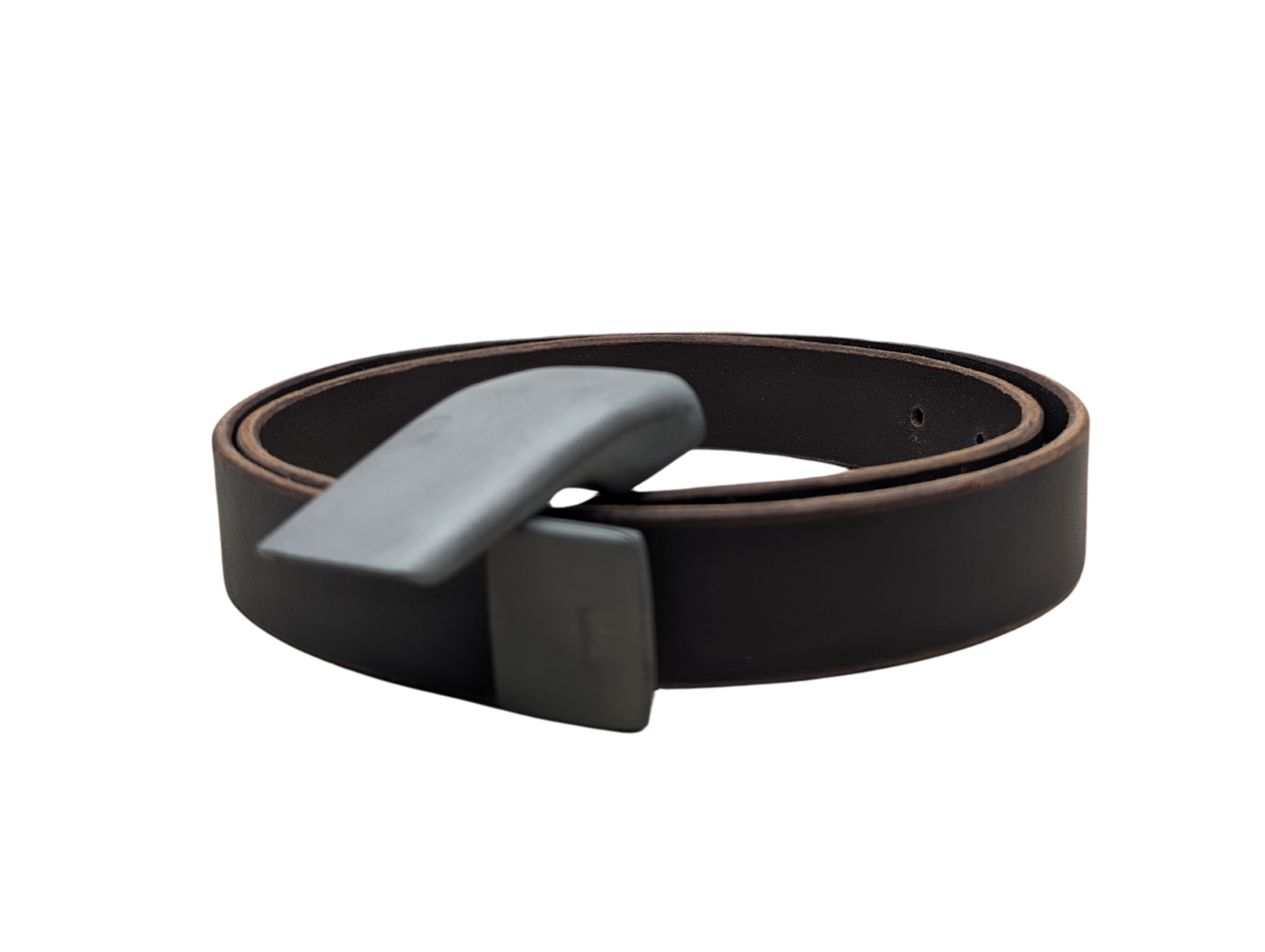

Building the most sustainable men's belt we think is possible

YOKU was born out of a desire to create a long lasting men's belt, but more than this YOKU seeks to champion the idea of 'One less thing'.

One less thing is the idea that the world will be a better place if people buy better, buy less and own more. We don't want you to merely buy a YOKU belt but to own it. Things you own are things you expect to have for the rest of your life.

To live up to this core promise and mission we needed to create the longest lasting belt and to achieve this we needed to deliver in 3 ways.

- Long lasting materials

- Long lasting design

- Long lasting construction

Materials

Stainless Steel 316

The YOKU belt by default is made from Stainless Steel 316.

316 stainless steel is a type of stainless steel that contains at least 16% chromium, 10% nickel, and 2% molybdenum. The high levels of chromium, nickel, and molybdenum give 316 stainless steel excellent corrosion resistance, making it ideal for use in harsh environments, such as marine and chemical processing applications.

Some other properties of 316 stainless steel include:

-

High strength: 316 stainless steel has a high tensile strength and can withstand high pressures.

-

Good formability: 316 stainless steel is relatively easy to form and shape, making it suitable for a wide range of applications.

-

Good fatigue resistance: 316 stainless steel has good resistance to fatigue, making it suitable for use in structural components that are subjected to cyclic loading.

-

Good creep resistance: 316 stainless steel has good resistance to creep, meaning it can maintain its strength at high temperatures or under consistent pressure

Something built from Stainless Steel 316 should be expected to last over a 100 years

Full Grain Leather

The YOKU belt is made from Full Grain Leather from Italy

Full grain leather is considered the most durable type of leather because it is made from the top layer of the hide, which has not been sanded, buffed, or altered in any way. This means that it retains the natural strength and durability of the hide, as well as its breathability and ability to develop a patina over time. Full grain leather is also often treated with oils or waxes to further enhance its durability and water resistance. In addition, full grain leather is typically thicker and more substantial than other types of leather, which can contribute to its durability. We use a vegetable tanned as this longer process ensures the colour applied to the leather is the entire way through so doesn't fade over time

We use Italian Full Grain leather as it is consistently recognised by artisans and leather experts as being the best and longest lasting belting leather

Neodymium Magnet

The YOKU belt employs Neodymium magnets to enable the interchangeable buckle/belt to work

Neodymium magnets are made from an alloy of neodymium, iron, and boron and are known for their strong magnetic properties and durability

The lifespan of a neodymium magnet depends on a number of factors, including the size and shape of the magnet, the quality of the material, and the environment in which it is used. In general, neodymium magnets are very durable and can last for many years if they are handled and stored properly.

One of the key factors that can affect the lifespan of a neodymium magnet is temperature. Neodymium magnets can lose their magnetic strength if they are exposed to high temperatures for extended periods of time. In general, neodymium magnets should not be used at temperatures above 176°F (80°C).

Another factor that can affect the lifespan of a neodymium magnet is corrosion. Neodymium magnets are prone to corrosion if they are exposed to damp or humid environments. To prevent corrosion, neodymium magnets should be stored in a dry place and kept away from water and other corrosive substances.

The magnets we used a fully housed inside the buckle and belt reducing their exposure to heat and humidity. In these conditions the magnets are expected to perform for hundreds of years

Design

The YOKU belt has numerous (patent pending) innovations that are designed to ensure maximum durability without compromising on form (how it looks) or functionality (how it works)

No moving parts

Unique to YOKU is our zero moving parts design based on the ethos in engineering if it moves it breaks. The buckle is a single piece of metal. The strap has two metal plates fused over it. Individually these components contain magnets that make the whole thing connect and that's it.

Under buckle hook vs traditional buckle

The YOKU buckle requires the belt to be passed under the buckle and then the internal hook on the underside of the buckle simply inserted into a belt hole. What people don't realise is this reduces the main cause of damage to the belt, the damage you cause every time you take it on or off where you have to crank the belt leather back on itself to get it back. The average belt gets taken on and off at least 5 times a day. A belt worn every day subjects the leather to 1500+ cranks. It's the number one reason why a leather belt will start to look busted up after only a few years .. even if the strap itself is the highest quality leather

Construction

Metal

When the Stainless Steel 316 is forged into the parts that make a YOKU belt it is 3D printed into a single component. We have done material analysis on the shape like you would do if you were creating high end automotive or aeronautical components to understand how these would perform under pressure, heat and other stresses to be sure that the shape and metal thicknesses are more than adequate to handle you owning and wearing it for 100+ years. The metal is not coated in any way, it is either used 'as is', brushed or polished. Typical belts will have a cheap metal that is then coated with something to give a it a particular look. The humidity and consistent movement in/around the metal day to day will cause this coating to peal over time.

Leather

When the Full Grain Leather is used we have opted for the simplest of construction options to reduce the number of areas where durability would otherwise be compromised.

To become a YOKU belt the Full Grain leather has only the following steps

- Cut to the exact width and length required

- Sand the edge to remove any fraying from the cut

- Bevel to create the rounded edge that makes it easier for the belt to go into the buckle

- Burnish, using heat and friction with wax to use the natural oils in the strap to create a water resistant edge to the leather by compressing the leather fibres

There is no dyeing, no stitching, no edging and no other embellishment. We subscribe to the idea that good design is when there is nothing left to take away.

It's not enough to choose sustainably sourced materials when you make things you have to build things that will outlast the owner. YOKU is built to last over a 100 years under even the most harsh conditions.