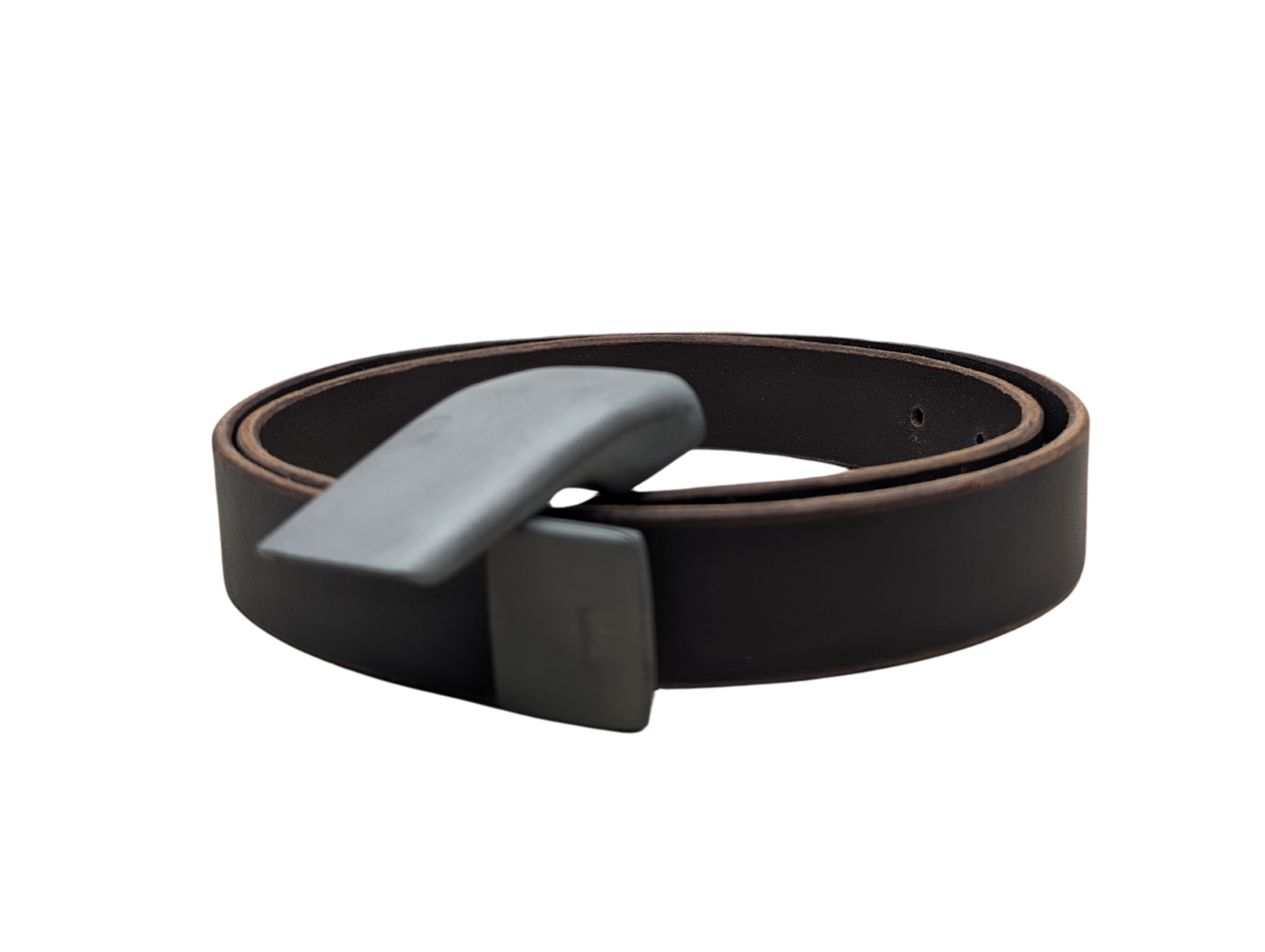

Plastic belt buckle? How our patented design made this amazing idea possible

Who on earth would even want a plastic belt buckle? Well, it turns out that if you're trying to make really durable belts then its actually worth looking into plastics. Plastic, as we all know, is a highly durable product. This is essentially the problem with plastic, but only if it's used for things that are disposable. As Mike Smith, CEO of ZeroCo often talks about in the context of their 'Forever bottles' plastics themselves aren't the problem, it's that we're using them once.

Men overwhelming are looking for a belt that will last as long as they will so investigating how you might use plastic was something we did here at YOKU.

Why wouldn't a plastic belt buckle work?

Belt buckles come in a variety of styles, literally dozens of different styles, but the are pretty much universal in one aspect. Traditional belt buckles have moving parts and things that move eventually wear down and/or break. In a material like metal, even if using the cheap zinc alloys normally found in belts, this may not be a problem. If you make a buckle out of stainless steel it should last for decades, even with movement. However, plastic is a relatively soft and porous material so simply having a plastic buckle that had movement all but ensures the belt won't last even a year.

A totally new design

When we set out to create the YOKU men's leather belt we had a very simple brief (in terms of functionality)

- Beautifully designed

- Well made

- Long lasting

- Interchangeable

- No moving parts

- No visible branding

We weren't (and still aren't) specifically set on a particular material for either the buckle or belt strap as long as it meets this brief. Solving for point 5 was what took over 3 years, countless designs, multiple prototypes and experimentation and one very long, expensive patent process.

The result is a single design that meets all these requirements.

How it works to solve point 5 is simply magical as this short video illustrates

Using a plastic belt buckle in the prototyping process

Once we had a few handmade metal prototypes that worked ok we started to explore manufacturing approaches. Fortunately in the 3 years we have been working on the designs the 3D printing technology has come a long long way and in late 2021 we were introduced to Additive Engineering in Melbourne who 3D print a range of metals and other materials, typicallly for use in medical grade or high end aerospace or engineering applications. Perfect for our unique, patented design.

On visiting the factory we discovered all the available materials that could be 3D printed to the very high tolerance (accuracy) that the design requires and unexpectedly discovered the option to print in plastic, more specifically Nylon.

I

A happy surprise was that 3D printed nylon had all the properties our belts needed including

- Hardness

- Durability

- Affordabilty

Relative to printing metal it made the ideal material to test our manufacturing process as we can print the parts in nylon for around 5% of the cost of 3D printing the same part in stainless steel.

Creating plastic belt buckles and belts for sale

We set out to create a long lasting, well designed, highly durable belt and truth be told we are mainly focused on selling a men's leather belt with a stainless steel buckle. Stainless steel (matte, polished or brushed) has the aesthetic we think our customers want but for anyone wanting a belt made with a plastic belt buckle we'd happily make one of these for you. They work equally well as their metal cousins and cost about 1/3 the price to make, which you will see reflected in the price you pay.

Plastic for disposable items is a terrible idea for the environment but using it to make a long lasting plastic belt buckle might be the best use for plastic we've seen so far!